Radius is the minimum producible inside radius for this material and not the recommended inside radius that you see on the bend allowance chart.

Copper sheet minimum bend radius.

For example the minimum bending radius of aluminium is determined by multiplying the sheet thickness by a factor of 2.

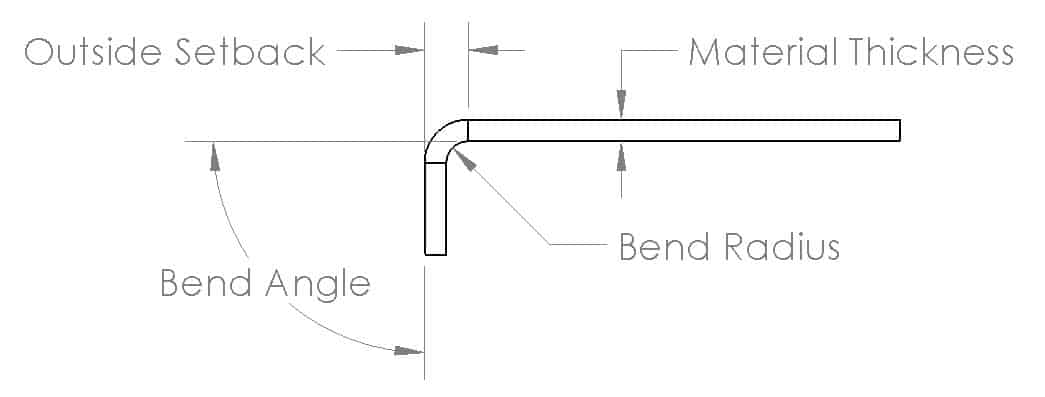

Minimum bend bend radius.

The overall diameter of the cable is given as 2 08 inches in the product catalog.

Minimum sheet metal flange bend length is required to avoid cracks in the bending area.

0 064 1 63 mm.

0 064 1 63 mm.

0 064 1 63 mm.

Minimum sheet metal flange bend length 3 x sheet thickness bend radius minimum hole diameter guidelines.

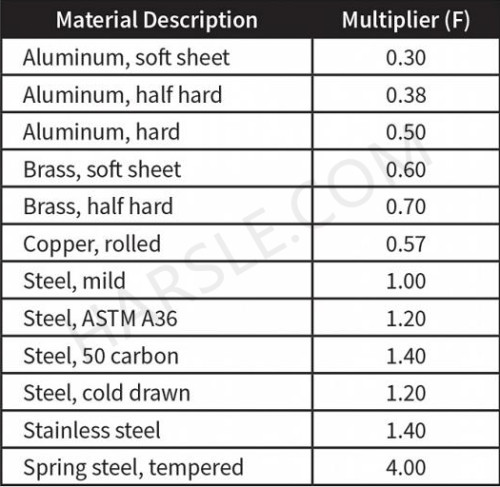

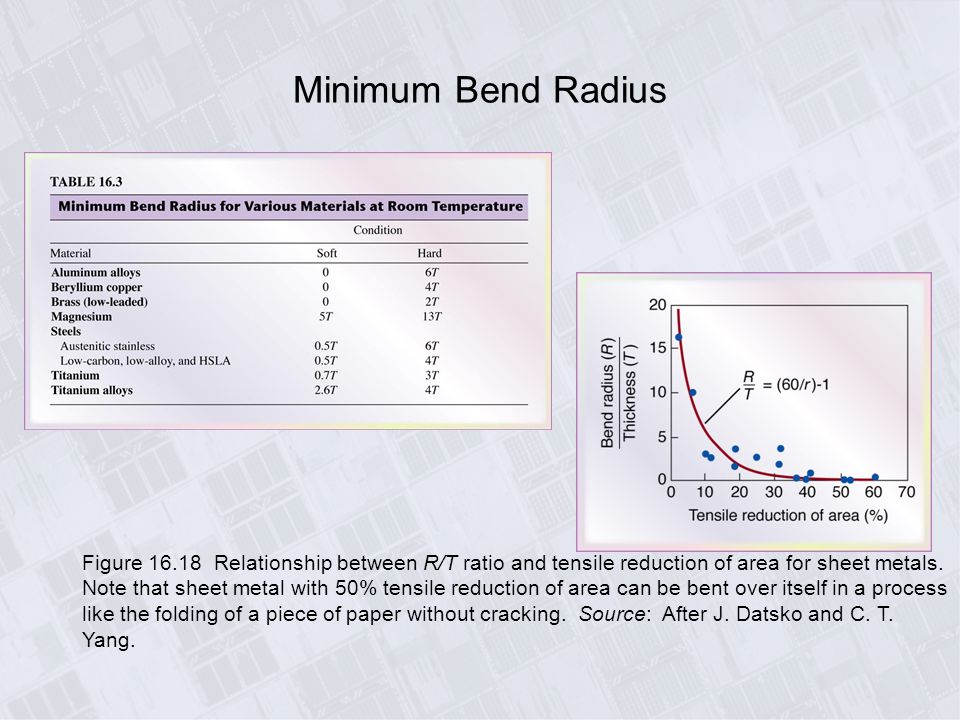

Each material to be worked also has its own conversion factor.

The die opening that the calculator recommends will achieve that.

Your input for die opening compares the calculators answers to the results of your choice of die opening.

Minimum bend includes minimum closeness of cutout to bend radius cold rolled steel 14 gauge 0 075 1 91mm.

0 064 1 63 mm.

For steel the factor is 1.

0 064 1 63 mm.

For ordinary low carbon steel plate anti rust aluminum plate yellow copper purple copper etc the inner radius 0 2 is no problem but for some high carbon steel hard aluminum super hard aluminum the use 0 2 radius will lead to bending fracture or the outer radius crack.

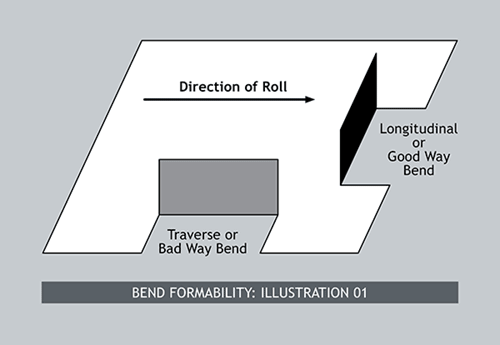

Grain direction is formed in metal in the direction in which the sheet was rolled at the steel mill.

In this case the minimum radius equals the respective sheet thickness.

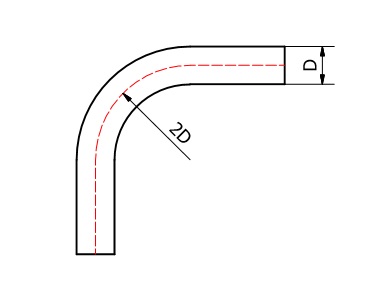

The minimum bending radius for this shd gc cable is approximately 12 5 inches.

It s true that the harder and thicker the plate is the greater the minimum bend radius.

So if the metal plate is 75 thick you would multiply 4 x 75 3 so your minimum inside bend radius would be roughly 3 times the thickness of the material in this case or 2 25.

0 064 1 63 mm.

Multiplying 2 08 inches by six we get 12 48 inches.

The minimum inside bend radius is even larger when bending with the grain.

The calculator is telling you the approximant minimum inside bend radius in the brittle material to avoid cracking that of 170 inches.

According to table 1 the minimum bend radius is found to be six times the cable s overall diameter.

If copper has to be bent a factor of 1 5 must be used.

It shall be equal to three times of sheet thickness plus bend radius.